The intecral progressive distlbutor DS can provde metered ubncalion for each lubncation point in the centralized ubrcation system. t has theadvantages of energy saving and high eficiency. t is used for vehicles, construction machinery, machine tools, wind power generation, plastic machinerypaper machinery, texile machineny, printing and packaging machinery ldeal products such as centralized lubrication. The ol outlet has a precise lubricanoutput, a compact design structure, easy and convenient installation, a buit.in check valve in the oll outet component, a plunger pair is precisely groundand a unique monitoring component.

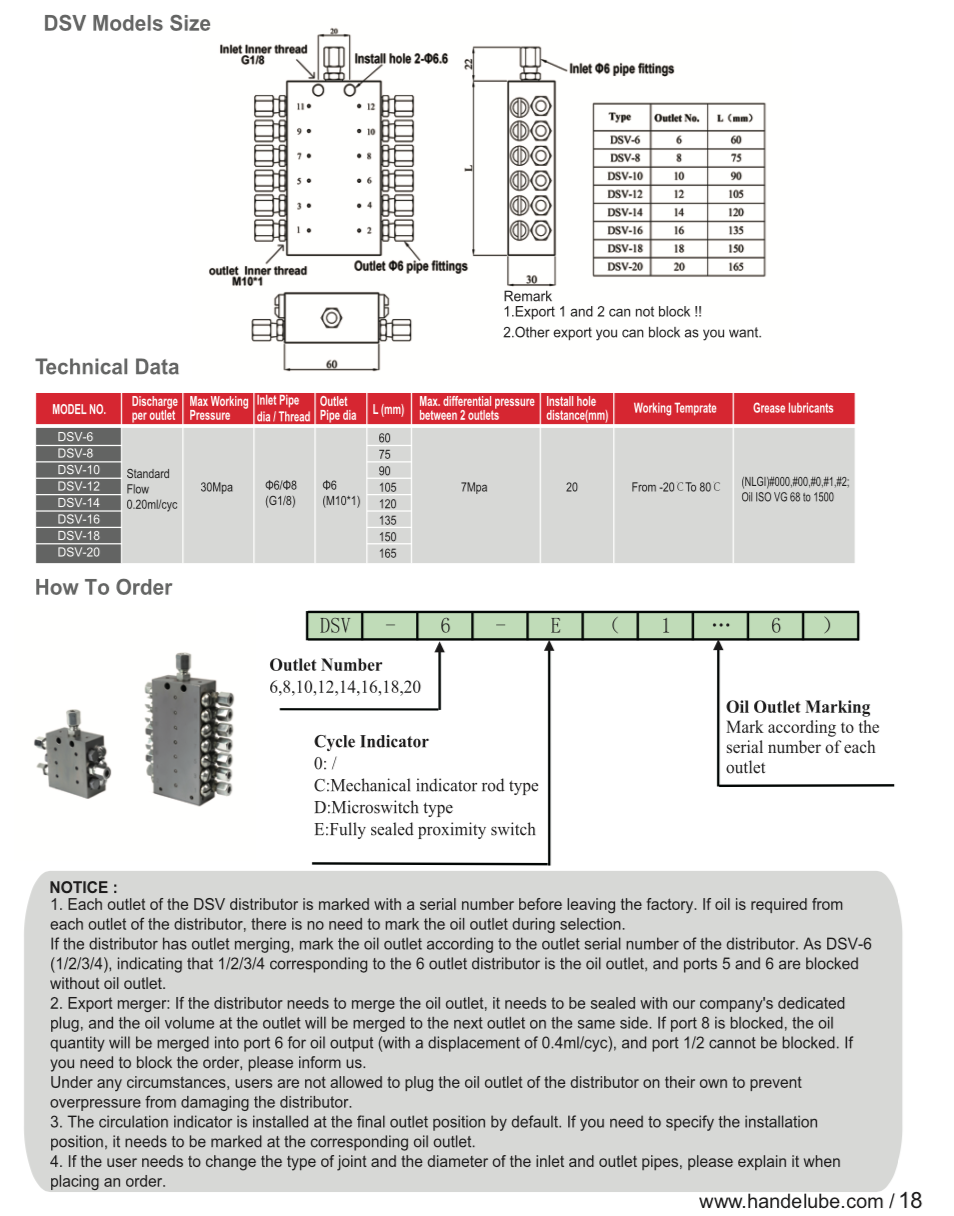

DSV progressive distributor has 6, 8, 10, 12, 14, 16, 18 or 20 oil outlets to choose from. Usually the single outet fow rate is 0.17mic, which can beprovided by removing the plug and the steel bal and replacing the oil outut block to provide a displacement of 0.34mic,0.51mic, etc which are integeimultiples of 0.17mlc.

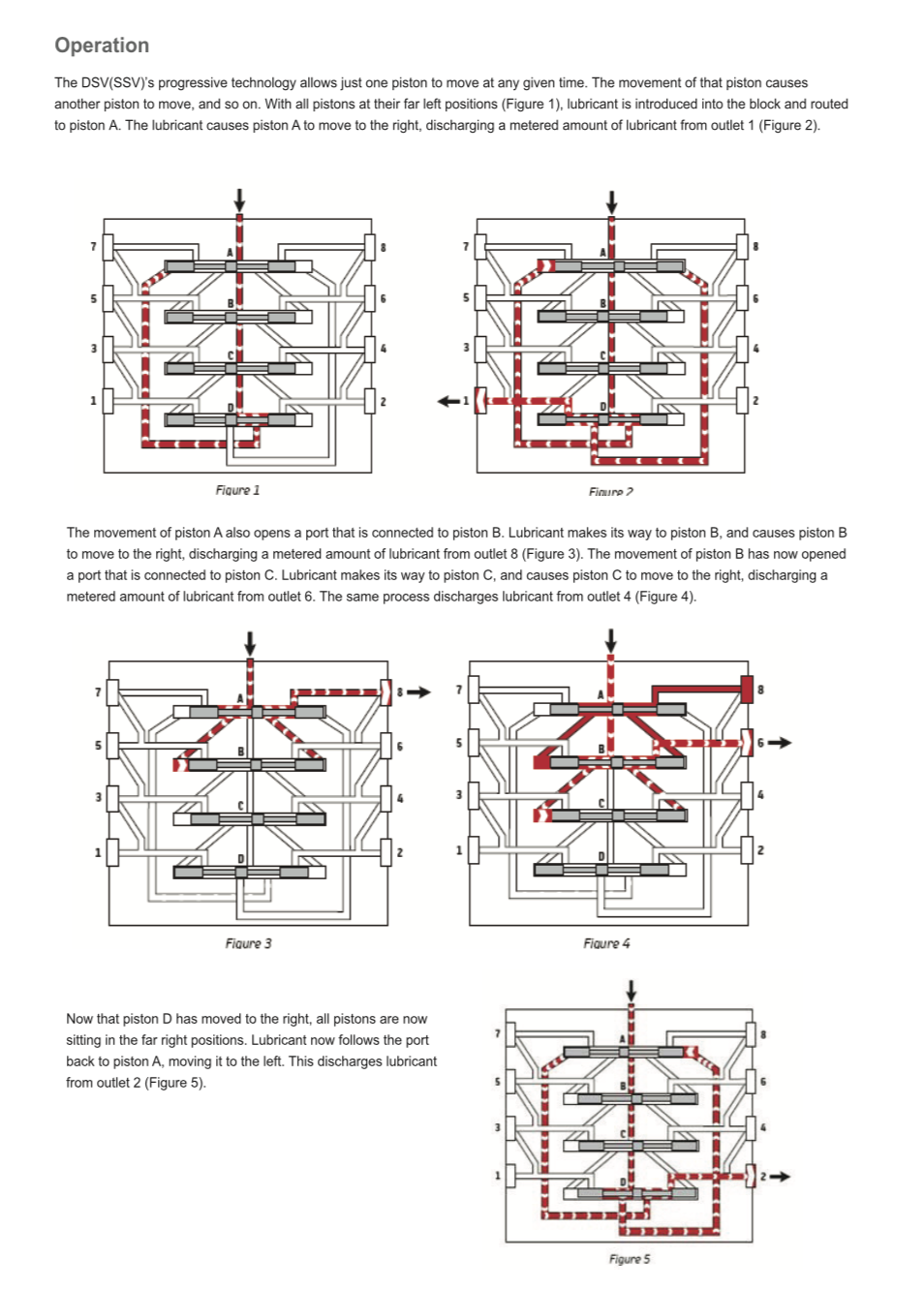

The plunger sleeve is connected by the ol hole in order to buld up the pressure. As long as the pressurized lubricant enters the olinlt, the distibutor willcontinue to operate in a progressive manner and inject oil with a constant displacement.

Once the supplied pressure lubricant fow stops, a the plungers in the dispensing will also stop moving. Therefore, by instaling a specific indicator toobserve the white movement of an oil outlet plunger, the operaing status of the entire distributor can be monitored.-0nce the blockage occurs,the alamcan be realized.

The plunger palr closest to the olinlet discharges the lubrcant from the ol outlet farthest from the olinlet, and the other plunger pairs in the valve bodydischarge a quantitative amount of lubricant through the next adjacent oil outlet.